- sophiaguo@sbmsolartech.com

- Home

- product

- Solar Lights

- Other Solar Products

- Street Light Pole

- Application

- Project

- About Us

- Blog

- Contact

Post time: 2021-11-29 13:59:30

As a clean and renewable energy, solar energy is increasingly being used in various industries. Solar street lights do not need to lay cables, do not need AC power supply, and do not incur electricity bills. They have good stability, long life, high luminous efficiency, and installation. It has the advantages of simple maintenance, high safety performance, energy saving and environmental protection, economy and practicality, etc. It is widely used in urban main and secondary arterial roads, communities, factories, tourist attractions, parking lots and other places.

Ordinary high-pressure sodium street lamps work when connected to the mains, and emit golden white light when in use. It has the advantages of high luminous efficiency, low power consumption, long life, strong fog penetration and no corrosion. It is widely used in roads, highways, airports, docks, docks, stations, squares, street intersections, industrial and mining enterprises, parks, courtyards, and plant cultivation.

The life of LED light source is far greater than 50,000 hours, that is to say, the average life of LED street light source is more than 10 years; while the life of traditional street light source (high pressure sodium lamp) generally does not exceed 6000h (less than two years), LED street light source is The life span of the high-pressure sodium lamp is more than 7-8 times.

In terms of installation, Tainengneng LED street lights do not need to lay cables, and do not need city electricity. Simply consuming electricity, solar LED street lights have huge economic advantages.

The traditional street lamp high pressure sodium lamp as the light source, the luminous efficiency is 120lm/W, the LED street lamp efficiency has reached above 180lm/w, the solar LED street lamp and the traditional street lamp have higher luminous efficiency under the same conditions, but because the light of the high pressure sodium lamp diverges everywhere A large part of the light cannot reach the road. At the same time, due to the difference in color temperature and color rendering index, the actual luminous effect of LED lamps is better than that of high pressure sodium lamps. The color temperature of high pressure sodium lamps is 2700k~3500k, the color is yellowish, and the color rendering index is 40%. It is difficult to see the true color of the object. The color temperature of the LED is 3500k~4500k, and the color rendering index can reach 80%. It can basically display the true color of the object. The light color is very suitable for our eyes and will not cause visual fatigue.

In summary, solar LED lights have obvious superior performance, especially the energy-saving effect is obvious, reducing greenhouse gas emissions, and solar energy is a safe voltage, avoiding many hidden safety hazards, not only saving energy in the later stage, but also reducing maintenance workload.

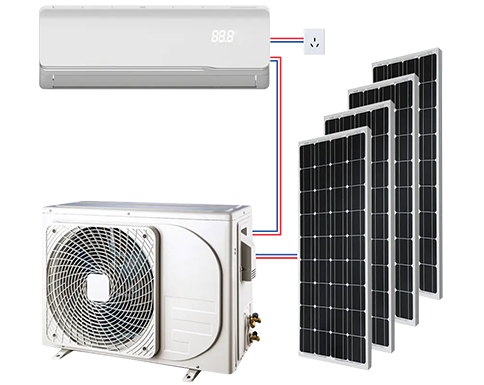

Solar street lights are composed of the following parts: solar panels, solar controllers, battery packs, light sources, light poles and lamp housings.

The solar panel is the core part of the solar street lamp, its function is to convert the sun's radiant power into electric energy, or send it to the storage battery for storage. Among the many solar cells, there are mainly three types: monocrystalline silicon solar cells, polycrystalline silicon solar cells and amorphous silicon solar cells.

In the eastern and western regions with sufficient sunlight, it is better to use polycrystalline silicon solar cells, because the production process of polycrystalline silicon solar cells is relatively simple and the price is lower than that of single crystal. In southern regions where there are more rainy days and relatively insufficient sunlight, it is better to use monocrystalline silicon solar cells because the performance parameters of monocrystalline silicon solar cells are relatively stable. Amorphous silicon solar cells are better in the case of insufficient outdoor sunlight, because amorphous silicon solar cells require relatively low sunlight conditions.

Regardless of the size of solar lamps, a good performance charge and discharge controller is essential. In order to extend the service life of the battery, its charging and discharging conditions must be restricted to prevent the battery from overcharging and deep charging. In places with large temperature differences, a qualified controller should also have temperature compensation. At the same time, the solar controller should have both street lamp control functions, light control, time control functions, and automatic load control function at night, so that it is convenient to extend the working time of street lamps on cloudy and rainy days.

Generally, there are lead-acid batteries, Ni-Cd batteries, and Ni-H batteries. The selection of battery capacity should generally follow the following principles: First, under the premise of meeting night lighting, store the energy of solar cell components during the day as much as possible, and at the same time It can store electric energy to meet the lighting needs of continuous cloudy and rainy days at night. The storage battery should match the solar battery and LED street lamp. The voltage of the solar battery must exceed the working voltage of the battery by 20~30% to ensure the normal negative charge to the battery. The battery capacity must be more than 6 times higher than the daily consumption of the load.

Solar street lights generally use LED light sources, with a long life span of up to +100,000 hours, low operating voltage, no inverters, and high luminous efficiency, up to 180 Lm/w.

The height of the light pole should be determined according to the width of the road, the distance between the lamps, and the illuminance standard of the road. There are many materials for light poles, such as Q235 steel light poles, which are made of high-quality Q235 steel, hot-dip galvanized and sprayed, and can be corrosion-free for 30 years. It is the most used light pole for street lights.

How to do daily maintenance of solar street lights? Solar street lights: lighting solutions for rural and remote areas

Please fill out the form below to start chatting with the next available agent.

Start Chat